Pyrolysis of Aluminium Waste

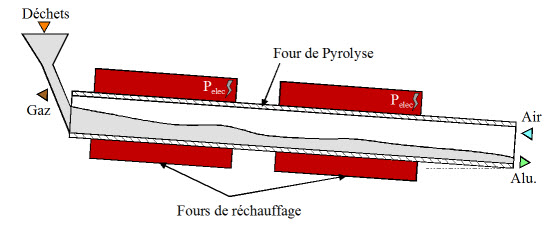

This acitvity was done in the frame of a partnership with Pechiney Research Center in Voreppe (which later became Rio Tinto Alcan) in 2004. The study dealt with the elimination of the organic coating of aluminium used for food preservation (cheese packaging, can...). The processing was consiting in a rotary kiln pyrolysis of the waste. To study the operation, Pechiney Research Center had developped a pilot plant (1 kg/h) where energy was brought to the process thanks to two electrical heaters (Shield furnace).

Sketch of the experimental device.

The goal of the partnership was to build a model

in order to understand the phenomena accouring within

the reactor and to allow designing a potential industrial

instllation.

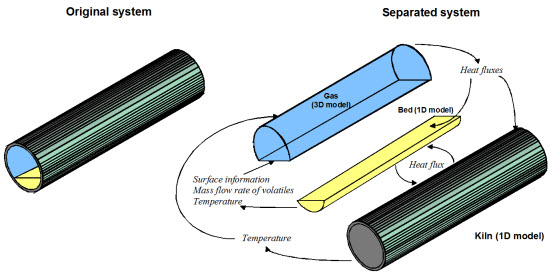

The model was relying on three sub-models : 1) a model

for the moving bed of solids, 2) a model for the kiln itself

and 3) a model for the gas phase were gaseous products of

pyrolysis where oxidized and contributed to the thermal

equlibirum of the process. These three sub-models where coupled

as it is illustrated in the following figure.

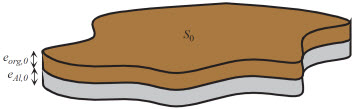

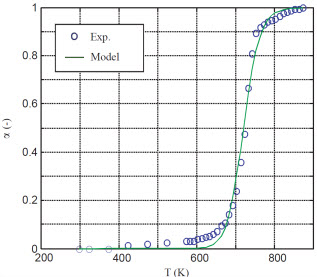

The bed model was composed of an assembly of non spherical particles (plan shaped particles with a width of organic coating) in plug flow inside the rotary kiln. As they were processed, the partciles were heated up under the effect of heat transfer with the kiln and with the freeboard gas. When the temperature reached a critical value, the orgnaic coating was pyrolysed with a first order reaction with respect to the actual organic content. This pyrolysis was releasing gaseous species that were oxidized in the freeboard where oxygen was available.

Bed Model.

Sketch of the particles being processed (left),

and conversion

of the organic coating as a function of

temperature (right).

The model decriving the behavior of the kiln was based on 1D

desciption of the evolution of the temperature along its axis.

The temperature profile (averaged over the circumference of

the kiln) was computed tahnks to an energy balance accounting for

axial conduction, heat transfer with the bed, heat transfer with

the gas (convective and radiative) and energy yield by the electrical

heaters.

The model describing the phenomena occuring in the freeboard gas

that was submited to homogeneous oxidation and to radiative heat

transfer was relying on the use of CFD and more precisely on the

use of Fluent.

One of the spcificity of the model was associted to its solving.

Because of the coupling that was occuring with the three sub-models,

an interative algorithm had been implemented and a specific software

developped.

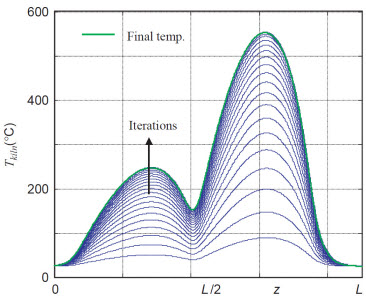

Algorithm for solving of the coupled model.

Algorithm (left), Software (right)

and iterative evolution of the results (bottom).

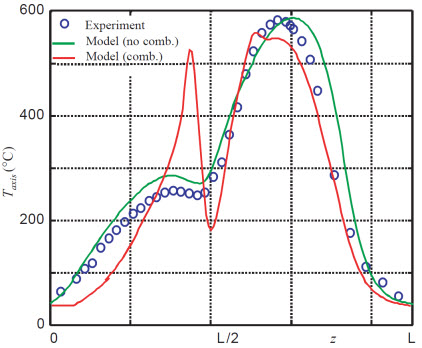

After validation of the model in a configuration where no thermal degradation was occuring (bed of inert material), the model allowed for a better quantification of the phenomena involved in the process.

Comparison (experimental/numerical) of the axial

profil of temperature.

Configuration with and without reaction.

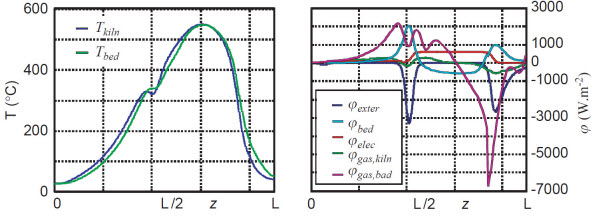

Résults of the model

Axial profile of temperature (left) and

specific heat fluxes.

Results of the model (continued.)

Profils of temperature (left) and

of oxygen mass fraction (right) in the

gas phase.