Model for cross flow gasifier

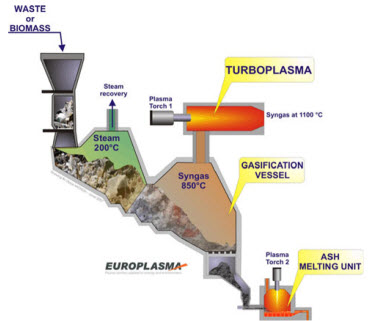

This activity took place in parallel with the thesis of Alexandre Deydier (T7 Modélisation d’un réacteur de gazéification en lit fixe) in partnership with Europlasma company. The goal of the study was to compute the composition of the product gas for the process CHO_Power for which the gasifier was a cross flow one.

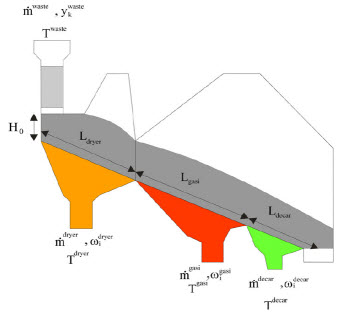

Because of the design of the reactor, which is divided into two stages (drying, gasification) the model has also be deivided into two such sections. Moreover, because the gasification section can be fed with two different gases (air and/or steam and/or enriched air and/or...) this has also been splited into two sub-sections.

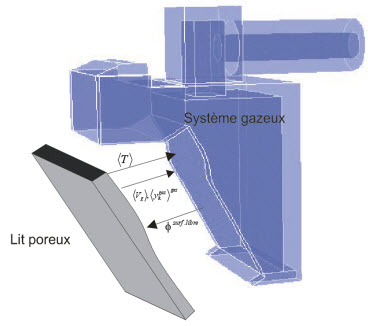

For each of these sections, the main issue is associted to the description of the physics and chemistry that occur within a reactive and moving porous bed. In order to take into account this specificity, hte volume averaging theory has been used. The governing equations (mass, energy and momentum balances) were written at the phase scale and averaged over a representative elementary volume.

sketch representing the volume avargaing concept

In the first step of the overall work, the discription of the phenomena

is 1D. The different properties of the bed depend upon its position from

the reactor supply. In the first section (drying), the energy involved in

the vaporisation of the moisture content is brought by the incoming air,

which is fed under the grate supporting the load to be processed. When this

air leaves the bed by its freeboard, its vapor content has increased (up to

its saturation point at the considered temperature) but it has no more

interactions with the bed of solids.

Things are different in the gasification section. Indeed, as the temperature

of the bed increases while it moves in this section, its organic content

pyrolyses, releases voltile matter and leads to the formation of char.

Dealing with this solid fraction, it is gasified (by H2O, CO2 or O2) within the

bed by hetrogeneous reactions. To some extent, the volatiles released during

pyrolysis begin to be oxidized (by the air fed under the grate) within the bed,

but most of the them reach the freeboard of the bed where they react with oxygen

that has crossed the bed without reaction (in the begining of the section, the

temeprature of the bed is not enough, and the oxygene just cross it

without raction). Hence some homogenous combustion reactions occur within the

freeboard where turbulence and radiation phenomena are also important. These

reactions lead to the release of important amount of energy which contribute to

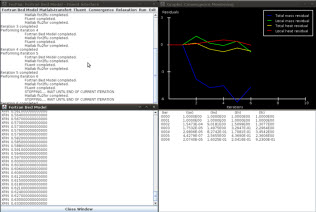

the heating of the load and to the thermal equlibirum of the reactor. CFD

(Fluent) has been used to represent the processes occuring within the freeboard,

and thanks to a coupling algorithm and to a software that has been created,

an iterative scheme has been implemented in order to automate the computing

sequence until convergence.

Sketch of the coupling between sub models.

Sketch of the solving procedure

Iterative algorithm (left) and softawre (right)

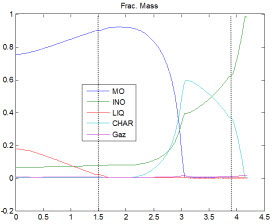

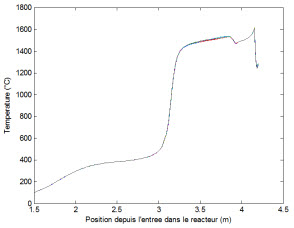

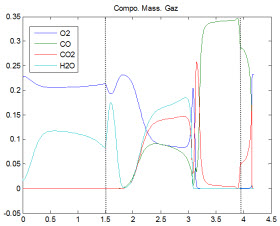

The results provided by the model are: 1)axial profile of temperature, bed composition (moisture, organic, gas, char and inorganic contents) and gas composition (O2, N2, H2, CH4, CO, CO2, C2s,...), and 2) 3D profiles of temperature, gas composition and radiative heat fluxes. All this data allow sketching a table containing the summary of the information describing the process and hence to optimize the operating conditions.

Results of the model.

Axial profile of bed composition (left), temperature

(right) and of gas composition (held in the bed) (bottom).

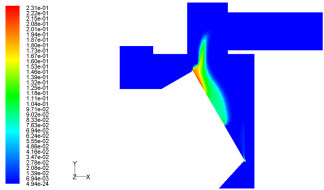

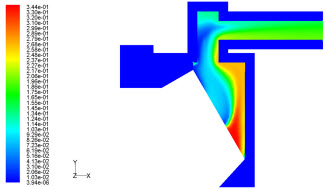

Results of the model (continued).

3D profiles of O2 (left) and CO (right)

in the freeboard of the reactor.

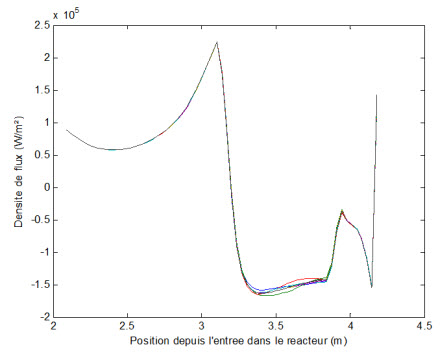

Results of the model (continued).

Axial profile of radaitive heat flux received by the

bed from the freeboard.

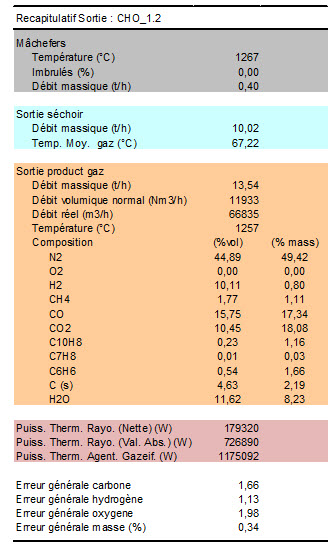

Results of the model (continued).

Summary of the input/output of the

configuration under study.