Fluidized bed incineration

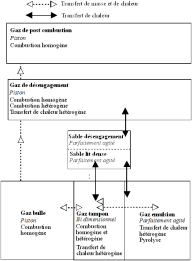

This activity started in 1999 in the frame of my PhD Thesis (Incineration d'un dechet modele: de l'approche physique aux simulations en lit fluidise). During this work, municipal solid waste was supposed to be composed of wood, cardboard and PVC. The hydrodynamics of the reactor was described using the two phase theory according to Werther's model (1980). In his work, Werther had created an interphase between the bubbles (where the main part of the combustion air was flowing) and the emulsion where pyrolysis was taking place. This model was modified to account for 2D diffusional combustion in this interphase region. The model for thedense bed was hence composed of three reactors: 1) a plug flow for the bubbles, 2) a CSTR for the emulsion and 3) a 2D Interphase region. With regard to the freeboard of the bed it was supposed to be composed of two CSTR: one for the disengageemnt and one for the post combustion.

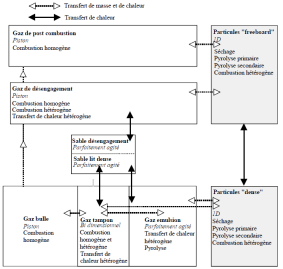

Sketch of the hydrodynamics of the model.

In the frame of this work, the waste (composed of wood, cardboard and PVC)

was supposed to undergo an instantaneous pyrolysis reaction leading to

four fluxes:

- a high heating value gas

- pure carbon particles

- elemental sulphur and nitrogen

- ashes.

During this intantaneous step, the particle size distribution of the solid

residue was supposed to be equal to the one of the incoming particles. Moreover,

the composition of the 4 above mentioned fluxes was computed so that elemental

balances were verified during the decomposition.

The solving procedure was relying on the overlaping effects. Firstly, profiles of temperature, composition and enthalpy associated to homogeneous combustion were computed using the concept of mixture fraction (assuming the local composition of the gas obeyed chemical equilibrium assumption) allowing for an important decrease in the number of tranport equation to be solved. These PDEs are solved using the finite volume method and an iterative procedure to acounet for the coupling between the different regions of the model. Also, neural network were used to decrease the computational time. From this first profiles, variations were computed from the results of the heterogeneous combustion of the solid residue. This effect was computed tanks to the kinetic of the combustion reaction, external mass transfer of oxygen to the surface of the particle and a particle size distribution balance. In a final post processing step, the pollutant production is computed in terms of HCl, SO2, SO3, NO and HCN.

Sketch of the processes occuring in the zones of the model.

The results of the model were presented as numercial experiments, giving a representation of the influence of the operating parameters.

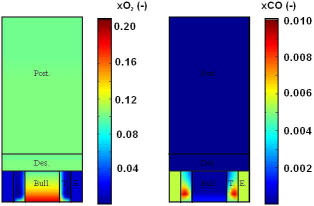

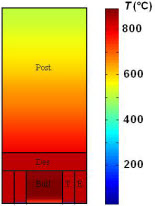

Résults of the first model.

Profile of molar fraction of O2 (left), CO (middle) and temperature

(right) in the reactor.

Results of the first model (continued).

Size distribution and temperature of the particles

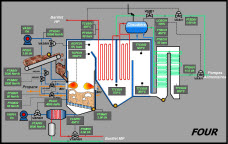

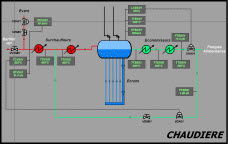

Improvements to the model were made in order to build a real time simulator for fluidized bed incineration. These improvements mainly consisited in the integration of the kinetics of homogeneous combustion and to the description of the reactor as a trasient one. This work was done in the context of Iliya Braiano Post Doctoral Position. ).

Interfaces pf the software SIMAPI.

Furnace (left), Boiler (middle) and energy recovery (right).

In the frame of the work of Besma Khiairi, (T3 Modélisation et simulation de l'incinération de boues en lit fluidisé) MSW was replaced by sludge, and the kinetics of both the drying and pyrolysis processes were accounted for. Hence, a global solving procedure was implemented and since then, it was not only possible to compute the composition and the temperature of the gaz at every location of the reactor but also the composition of the particles of sludge.

Sketch of the processes occuring in the zones of the model.

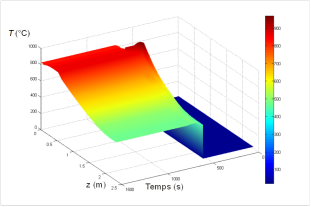

Spatiotemporal evolution of the temperature

of the sludge particles after their introdcution

in the reactor at t=550s

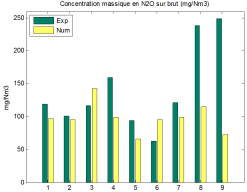

The last work that was done in this research field was in partnership with Veolia Research Center (VERI). The main part of this work was done by Abderrahmane Benzaoui (PD 5 ) and was devoted to the integration of a specific reaction pathway that allow estimating the N2O production during incineration of urban sludge. In the frame of this work, numerical results were also validated against industrial results obtained from a fluidized bed incinerator of Veolia group.

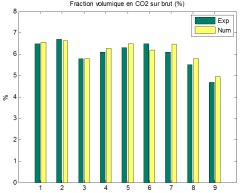

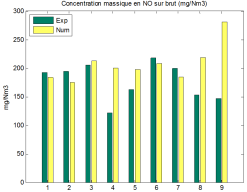

Comparison of numerical to industrial results.

CO2 (left), NO (middle) N2O (right).