Torrefaction of Biomass

This activity started in 2007 in the frame of the MSc internship of Mickael

Philippeau (M8) devoted to the modeling and the simulation of

a reacteur for torrefaction of wood particles.

This activity was then continued in the frame of the consortium PREBIOM

(01/2008 to 12/2011)

devoted to the study of torrefaction of biomass from Aquitaine conutryside.

During the period of this consortium (composed of 10 Parteners (IFPEN, UPPA,

OCEOL, Arvalis, CAFSA, COFELY, Aquitaine Electronique, Conseil Régional

d'Aquitaine, Communauté de Communes de Lacq), the behavoir of 4 biomass

(pine wood, corn stover, fescue and triticale), was studied in torrefaction

conditions. Thanks to a first analysis using a commercial TGA (Netzch Jupiter

449C), the kinetics of the thermal degradatin of these materials have been

evaluated.

Exemple of TG/DTG data obtained in torrefaction conditions.

Influence of the initial size of the particles. Heating rate 10°C/min.

a) Corn Stover, b) Fescue, c) Triticale, d) Pine Wood.

During the consortium, a continuous torrefaction reactor (2 kg/h) was also designed and built where pine wood was processed. This reactor was of the countercurrent fixed bed type with a continuous extraction of solid products thanks to an endless screw. The experiments allowed understanding the phenomena occuring within the device and to study the influence of the operating parameters. It in the frame of this consortium that Cecile Casajus defended her PhD Thesis (T6 Etude de la torréfaction de déchets de biomasse régionale).

Torrefaction pilot plant (2kg/h).

Temperature profile along the axis of the reactor (0: bottom, 1.2m top).

Influence of the torrefaction temperature.

In parallel to this conosrtium was also developped a high capacity thermobalance. This device, bases on the same concept as a commercial TGA, allow for the processing of load of biomass up to 500g. Thanks to the complete tightness and to its facilities (Input and Output Mass Flow Rates, condensation and collecting of tars) it is possible to follow not only the evolution of the mass (as a function of time/ temperature) of the solid held in the device, but also the evolution of the by-products yields and to verify the overall mass balance of the operation (with less than 5% error). Moreover, thanks to a gaseous micro chromatography apparatus and to a High Performance Liquid Chromatography (with a refractometer as detector) it is also possible to quantify the permanent gas (CO, CO2, CH4, H2 and C2) and tars yields (formaldehyd, formic acid, acetic acid, lactic acid, hydroxyaceton, acetaldehyde, methanol, phenol and furaldehyde).

High Capacity Thermobalance

Left: Rear View. Center: Side view. Right: Front view.

Exemple of results obtained with the high capacity thermobalance:

Influence of the operating conditions on the

yields obtained with torrefaction of corn stover.

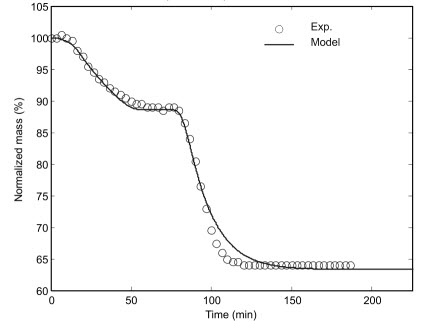

A 2D volume averaging concept based model was also developped in order to quantify the influence of the different phenomena occuring during torrefaction This work was possible thanks to a partnership with the computing center from UPPA and more precisely with Stephanie Delage. The goal of the model is to propose a chemical pathway for torrefaction including the by-products and the corresponding kinetics satisfying the elemental balances of the material to process.

Comparison of numerical versus experimental results.

Evolution of the mass of the sample.

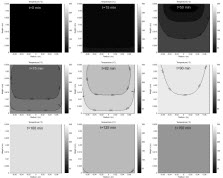

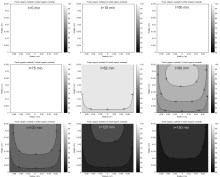

Results of the 2D model. Transient Evolution of:

moisture content (left), temperature (center) and

orgnaic material content (right).