Turboplasma reactor

This activity started in 2007 in the frame of the PhD Thesis of Alice Fourcault

(T5 Modelisation d'un étage haute température

alimenté par une troche à plasma pour la dégradation des goudrons présents

dans les gaz de synthèse) in partnership with Europlasma Company. It was

followed in the frame of the grant gained from the National Research Agency

(ANR BioE 2009 Turboplasma) still with Eurplasma company whare took place the PhD

thesis of Romain Demarthon (T8

Conception et modélisation d’un étage haute température pour la dégradation

thermique de goudrons).

The goal which was looed forwared in these investigations was to build a tool

that allow designing of reactor for cleaning of gases coming from a gasification

stage as in the case of the process CHO_Power.

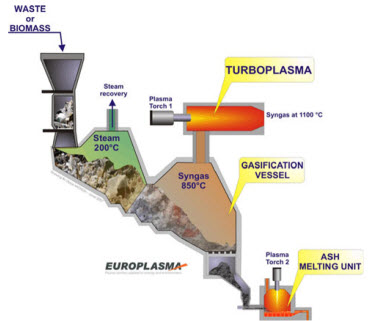

The aim of this reactor, Turboplasma , is to convert unburned particles and tars into lighter molecules. Tars are craked while unburned particles are gasified. Compared to classical process for tat removal, the main advantage of thermal cracking is associate to the fact that the lower heating value of these "pollutants" is kept in the syngas. This process however demands that high temperatures be reached what is fulfield in the Turboplasma reactor thanks to non transferd plasma torch.

Sketch of the desired objective.

Un oreder to reach this design goal, CFD (Fluent) has been used. In order to account for the chemical reactions involved in the reactor, a specific reaction pathway was included to the commercial software as well as the physical and chemical properties asscoited to the presence of a plasma inside the reactor. Heat transfer within the refractoried walls of the reactor is also accounted for. Finaly, because of the carbonaceous particles held in the gas flow entering the reactor, a dicrete and reactive phase was also included in the overall model. The gasification reaction invloved are the ones with H2O, CO2 and O2.

Thanks to this design tool, several geometries for the reactor have been qualified so that their advantages and drawbacks be listed. From this fist analysis principles for the design of the reactors were produced and the building of the first Turboplasma reactor was finished on the CHO_Power in Morcenx (Landes, France). This reactor is fited with a plasma torche of 2MW nominal input.

Overall view of the CHO_Power unit in Morcenx (Landes, France).

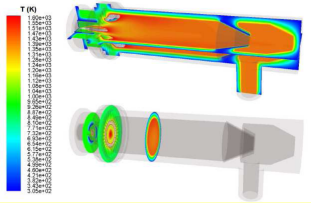

Numercial results obtained for the 2MW Turboplasma

Temperature profiles

To fulfil some research requirements, a second turboplasma reactor was also built in Morcenx (Landes, France) in the frame of the National Research Agency support (ANR 2009 BioE). On this R&D platform, the reactor (fitted with a 300kW plasma torch) was associted to a fluidized bed gasifier hence consituing the process Kiwi.

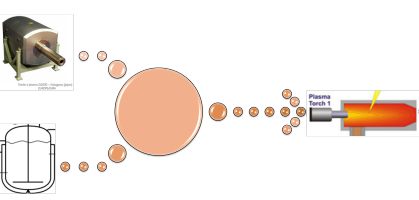

Reactor Turboplasma for the kiwi Process (Morcenx, France).

Numercial results obtained for the 300 kW Turboplasma

Mass fraction of Naphtalene Profiles.