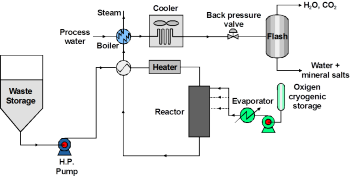

Oxidation of aqueous waste in supercritical water.

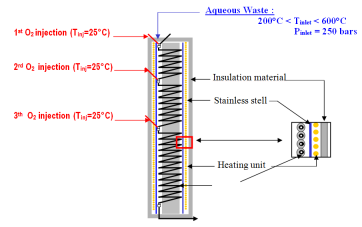

This activity had been initiated by J. Mercadier in the Laboratoire de Génie des Procédés de Pau (former LaTEP) in the frame of the PhD Thesis of Patrick Dutournié. It was followed by the work of Stephanie Vielcazals T1 which were devoted to the modeling of a plug flow reactor with a triple ports oxygen supply.

Triple ports oxygen injection reactor.

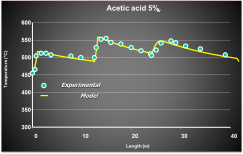

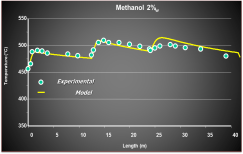

According to this model (based on plug flow assumption), internal profiles of temperature and composition were computed and compared to experimental data (internal profiles of temperature). The comparison showed very godd agreement.

Internal profiles of temprature along the reactor (numerical and

experimental)

obtained with acetic acid (left) and methanol (right).

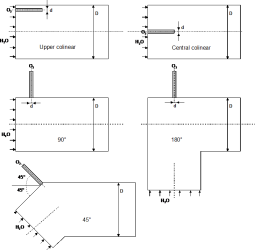

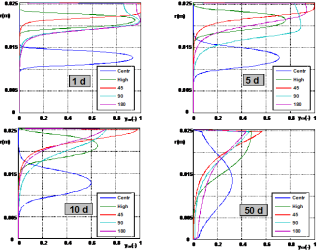

CFD Had also been used for this reactor in order to properly design the injection ports. 5 geometries were indeed studied.

Exemples of CFD computation for the triple ports injection reactor

Geometries i nvestigated (left), mass fraction of O2 (right).

These models allowed HOO Company (which later became Innoveox) to design and build industrial reactors of 100 kg/h nominal capacity.

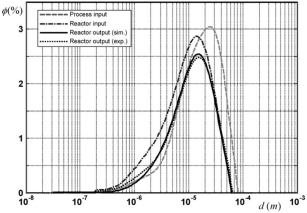

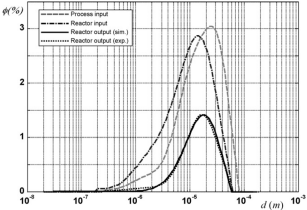

Other work, which was done during the PhD Thesis of Florent Mancini ( T2 ) were devoted to the oxidation of solid particles in a tank reactor. According to a model computing the rate of shrinkage of the particles (based on kinetics and external heat transfer limitation) the particle size distribution has been computed as a function of the incoming one and of the operating conditions prevailing within the reactor.

Evolution of the particle size distribution in the process

Influence of the temperature (left: 300°C, right 330°C).

Finally, still in the frame of the thesis of Florent Mancini, optimisation for energy recovery computations were done using software ProSim Plus. The allowed optimizing the energy recovery efficiency of the overall process.

Optimization of energy recovery efficiency:

Initial process (left) and optimised one (right)